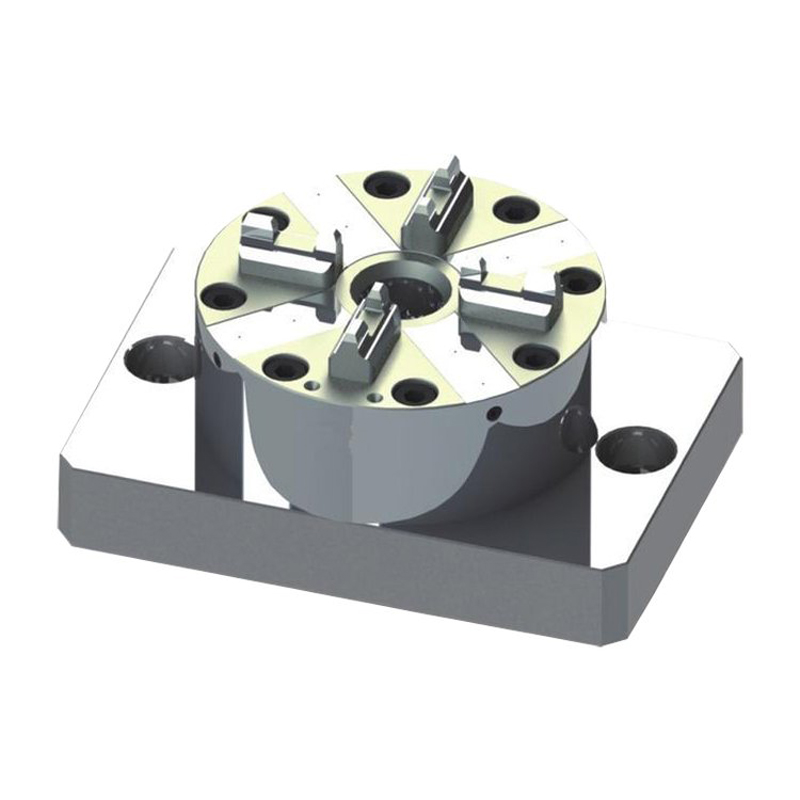

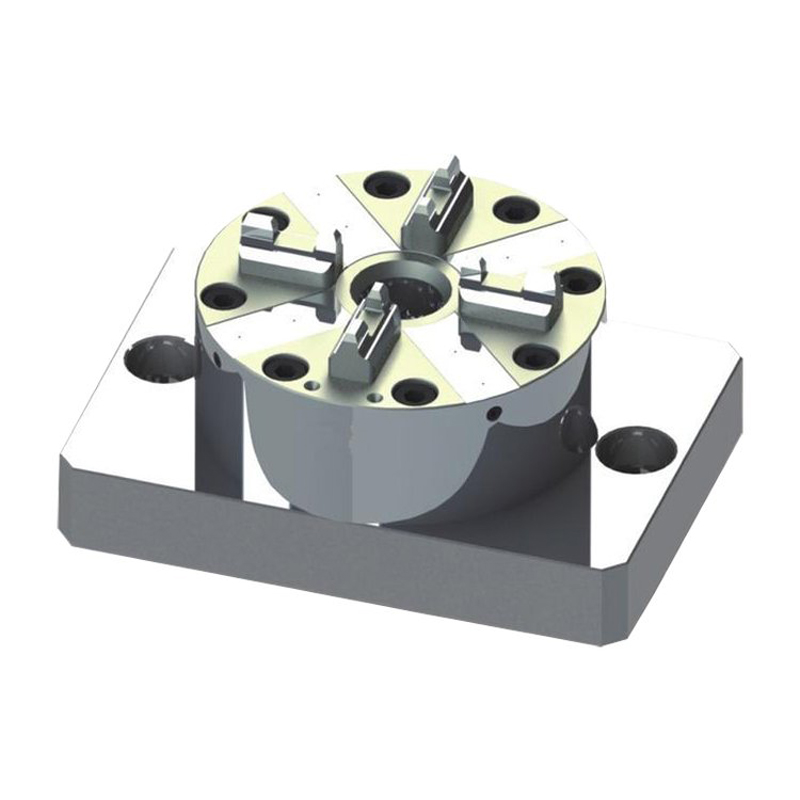

Chucks can be divided into types in detail: "manual chuck", "pneumatic chuck", "hydraulic chuck" and "electric chuck". We will not make comparisons. Of course, each has its own advantages and disadvantages. Let’s explain the advantages of pneumatic chuck in detail:

1. Efficiency: Pneumatic chucks have significantly improved work efficiency, especially in clamping. Its quick clamping and release functions can significantly reduce operating time and improve production efficiency.

2. Simple and convenient: The pneumatic chuck has a simple structure and no complicated parts. The installation and maintenance are relatively convenient and labor-saving, and it is not prone to errors.

3. Consumables and energy saving: The pneumatic chuck is a device with no consumables and no energy consumption. It only needs to provide compressed air to operate normally. Compared with other types of chucks, it does not require additional electric or hydraulic systems, making it more environmentally friendly and cost-saving.

4. High safety: In the machinery industry, safety is crucial. The pneumatic chuck has undergone strict factory testing, including pressure testing and error testing, to ensure its zero-risk use. Therefore, users can use pneumatic chucks with confidence and meet safety requirements.

The safety factor is extremely high. In the machinery industry, everyone knows that safety is the most important thing. Therefore, pneumatic chucks have strict factory inspections, pressure tests, and error tests, all of which are zero-risk. Therefore, pneumatic chucks It can be accepted and used by the majority of users in the field.