DIN980 all-metal lock nuts are also called effective torque lock nuts, which are usually called stamping self-locking nuts. Effective torque refers to the torque generated by screwing in the nut without axial load. Due to the locking function of the nut , also called locking torque.

When the nut is screwed in, the diameter of the deformed thread of the nut itself or the built-in metal locking ring is slightly smaller than the external thread of the bolt. The nut needs to overcome the frictional resistance, and the frictional resistance also successfully prevents the nut from loosening without external force. DIN980 mainly includes DIN980V type and DIN980M type according to its locking form. Today we mainly talk about the DIN980V type;

1. Basic information of DIN980V all-metal lock nuts

DIN980V specification covers ≤M4-M39, thread tolerance is 6H- (before coating), available for coarse and fine threads. The main materials are carbon steel and stainless steel; the performance grade of coarse tooth carbon steel is grade 8 and grade 10, and the coating is generally blue and white zinc, passivation, environmental protection galvanizing, zinc-nickel alloy coating, etc. Generally, the tolerance before coating is 6g/6H, and after ordinary galvanizing, it is generally 6h/6G. In the test of go-no-go gauge, the tolerance fit is still affected by the thickness of the coating, and other coatings may not fit.

Second, the difference between DIN980V and 980M:

1. Different locking forms

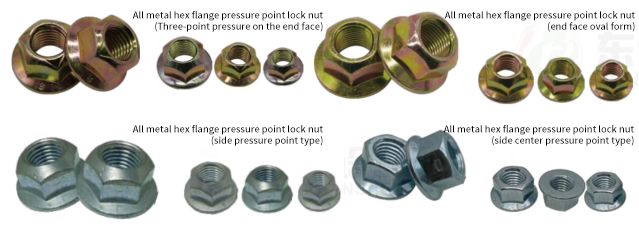

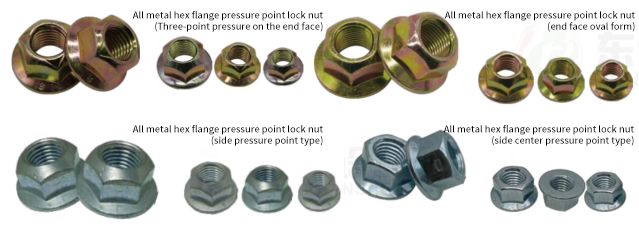

①The 980 V type relies on the thread deformation position of the nut itself to lock and prevent loosening. Common forms include: three-point end face type, elliptical type, and side extrusion type.

②The 980 M nut is embedded with a metal locking piece, and the locking ring is used to prevent loosening, as shown in the figure:

2. Different locking principles

①The locking principle of the 980 V-type nut is: stamping through the die, the thread of the nut itself has about 3 teeth deformed, and the inner diameter of the nut thread is slightly smaller than the outer diameter of the bolt thread after deformation. Therefore, the friction between the threads after the nut is tightened is much greater than that of ordinary threads, which can effectively prevent loosening.

②The locking principle of the 980 M type nut is: the nut is embedded with a heat-treated metal sheet. The inner diameter of the metal sheet is slightly smaller than the outer diameter of the bolt thread. After the nut is tightened, the metal sheet clamps the bolt thread, which can effectively prevent Loose, anti-seismic effect.

3. Installation method

The lock nut must be tightened with tools (such as a ratchet wrench) when installing. It is recommended to pre-apply grease when installing stainless steel nuts to prevent nut locking problems during quick installation.

4. Suggestions for use

The lock nut can be reused, but it is not recommended to disassemble and install it repeatedly. After dismantling and installing for many times, the locking torque of the nut will drop significantly.

5. Mechanical properties

Regarding mechanical properties: in line with DIN980V, the performance grades of coarse teeth are mainly grade 8, grade 10 and grade 12, etc. The marking method of DIN980V fine tooth mechanical properties is different from that of coarse tooth. Lock nut performance verification includes five screw-in and screw-out torque requirements, which can be implemented in accordance with ISO 2320 to ensure its locking performance.